Trump Administration’s New Tariffs: A Decision with Major Consequences for Global Supply Chains

Had it been announced just 24 hours earlier, it might have been taken as an April Fool’s joke…

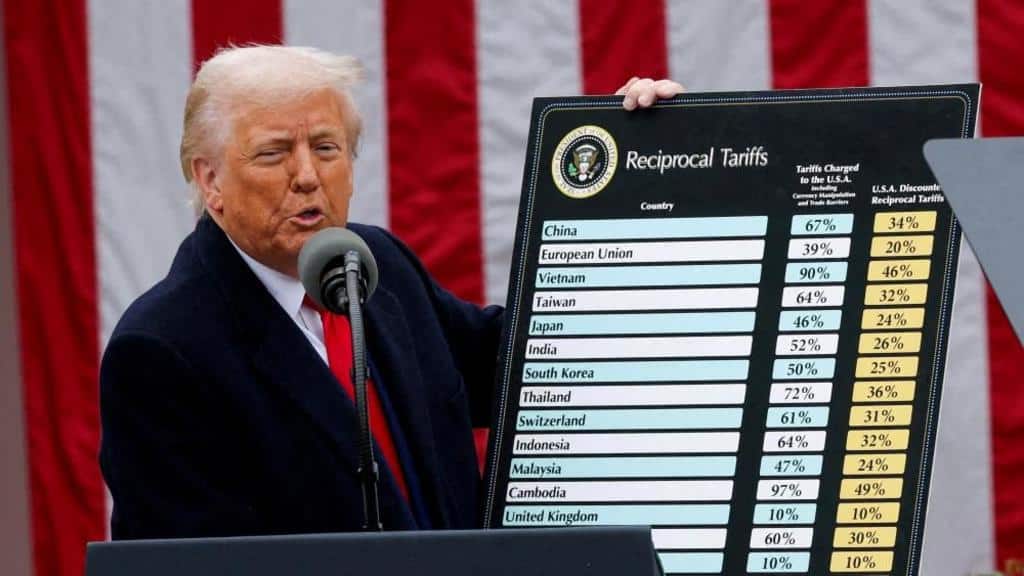

Yet, on April 2, 2025, President Trump stood at the White House and proclaimed what he called “Liberation Day,”revealing a set of tariffs of historic proportions.

In Europe, we woke up to the announcement on the morning of April 3, immediately grasping the scale of a decision that is far from a mere policy adjustment — it marks a brutal rupture in the balance of global trade and in the stability of international supply chains.

But was this tariff revolution conceived with any real understanding of modern supply chains? According to our expert analysis: clearly not.

What may appear simple on a presidential flipchart is, in reality, a high-risk decision with widespread implications for the global economy.

1 – Historic and Sweeping Tariffs

The Trump Administration has introduced a universal 10% tariff on imports from nearly every country, with only two strategic neighbors — Canada and Mexico — temporarily exempt. These tariffs impact traditional allies and competitors alike.

Additional reciprocal tariffs targeting countries accused of “unfair trade practices,” based largely on bilateral trade deficits: China: 54%, Vietnam: 56%, Switzerland: 31%, European Union: 20% Japan: 24%. These represent a level of taxation not seen in nearly a century.

A more discreet yet strategically critical move: the abolition of the de minimis rule, which had allowed imports of small parcels (under USD800) without taxation. This hits cross-border e-commerce, express shipping, small importers, and threatens to cause a domino effect across freight, warehousing, and customs systems.

Immediate implementation, with no transition period for businesses, only intensifying the shock for affected countries.

2 – An Approach Disconnected from Supply Chain Realities

2.1 – A Simplistic Logic in a Hyper-Complex System

The White House’s logic is based on reciprocity: “If you tax our goods, we’ll tax yours.”

However, this approach ignores the essential complexity of global supply chains. A smartphone assembled in Vietnam may contain components from Korea, Japan, China, and the U.S. The notion of a product’s “country of origin” becomes blurred.

These policies appear to disregard intermediate trade flows, regional sourcing strategies, or the reality of distributed manufacturing models.

2.2 – No time to adapt

Major supply chain transformations are typically planned months or even years in advance. Reconfiguring production, reorganizing a logistics network, or renegotiating supplier contracts are complex processes that cannot be improvised.

By imposing tariffs overnight, the Trump administration has pushed companies into emergency mode, with no time to analyze, model, or deploy alternatives. For goods already in transit, this means unbudgeted cost increases and disrupted supply plans.

2.3 – Devastating impact on SMEs

Large companies can rely on dedicated teams, consultants, and digital tools.

SMEs, however, lack visibility and capacity. They often don’t have the financial or organizational flexibility to redesign their sourcing strategy quickly. SMEs that depend on imports for over 70% of their product lines may see their profitability collapse within weeks.

2.4 – Major strategic inconsistencies

The administration’s official narrative promotes reshoring and domestic manufacturing. But the implementation contradicts that goal: the raw materials needed to build factories (steel, aluminum, equipment) are also being taxed.

Moreover, new production facilities can take up to 24 months to go live. In the meantime, companies must continue working with existing setups — often in countries now penalized by tariffs.

2.5 – Lack of global vision

The end of the de minimis rule, coupled with the cascading effect of new tariffs, impacts far more than importers. It affects express shipping providers, logistics consolidation hubs, e -commerce warehouses, 3PL partners, reverse logistics and returns.

The result? A complex domino effect across both upstream and downstream logistics, difficult to contain.

3 – What are the concrete risks for companies ?

Explosion of import costs: For businesses sourcing from Vietnam or China, costs could rise by 30% to 50%, forcing a complete rethink of financial models and business strategies.

Price increases: Companies must choose between absorbing the impact, sacrificing margins, or passing costs to customers, each with complex trade-offs around competitiveness, profitability, and market positioning.

Margin pressure: In low-margin, highly competitive sectors (retail, electronics, apparel), the additional costs could become unsustainable without major business model adjustments.

Market share erosion: Companies that fail to adapt quickly risk losing ground to more agile or better-positioned competitors.

Strategic instability: The inability to anticipate further measures (extensions, exemptions, retaliation) limits the willingness to invest or initiate long-term changes.

4 – What are the strategic options to distribute or absorb these costs ?

4.1 – Geographical diversification

It is more critical than ever not to rely on a single country. Companies can seek alternative suppliers in countries not affected by the new tariffs. This involves qualifying vendors, assessing country risk, verifying local capabilities, and possibly restructuring procurement strategies.

4.2 – Logistic and industrial repositioning

Companies with global footprints can reorganize their flows: importing components instead of finished goods, shifting final assembly to non-taxed zones, or outsourcing locally. For example, establishing an assembly site in Mexico could allow for tariff exemptions while maintaining proximity to the U.S. market.

4.3 – BOM optimization

One of the most effective levers is to redesign product components. Replacing a heavily taxed part with an alternative of different origin can reduce exposure — as long as product performance and compliance remain intact. This requires close collaboration between procurement, R&D, and quality teams.

4.4 – Refined pricing and commercial strategy

Cost increases can be distributed across customer segments. Premium or high-value products can better absorb price hikes, while others may require repackaging, resizing, or alternative SKUs.

4.5 – Supply Chain lifecycle management

Companies should differentiate between inventory in stock, goods in transit, and future production. Some can frontload purchases before tariffs apply; others may pause non-essential flows or explore nearshoring options to mitigate exposure.

4.6 – Supplier and partner renegotiations

Contracts may need to be revised to share additional costs. Options include temporary discounts, updated incoterms, or co-financing of logistics and customs duties.

5 – Conclusion : a wake-up call, and an opportunity !

This tariff shock will clearly separate resilient, agile businesses from those that are rigid or unprepared. It forces supply chain leaders to reclaim control, invest in visibility, improve scenario modeling, and strengthen operational resilience.

One thing is clear:

The companies that truly understand and master their supply chains — in all their complexity, costs, and flows — will be tomorrow’s winners.

Is your supply chain ready to absorb a 20–50% cost surge? Have you mapped your flexibility zones? Can you simulate multiple scenarios within 24 hours?

If any of these questions give you pause, now may be the time to rethink your model — with experienced partners by your side.