Supply Chain + Sustainable Development = Happy Wedding?

What is sustainable development?

The first definition of sustainable development appeared in 1987 in the Brundtland Report published by the UN World Commission on Environment and Development:

“Sustainable development is development that meets the needs of the present without compromising the ability of future generations to meet their own needs.”

Concretely, sustainable development is a way of organizing society to enable it to exist in the long term. This implies taking into account both present and future imperatives such as the preservation of the environment and natural resources, or social and economic equity.

The objective of sustainable development is to define viable schemes that reconcile the ecological, social and economic aspects of human activities: “3 pillars” to be taken into account by communities as well as by companies and individuals.

The aim of sustainable development is to find a coherent and viable long-term balance between these 3 issues.

In other words, to ensure the sustainability of the model, development must be liveable, viable and equitable

What is a Sustainable Supply Chain and Why?

By making the link with the definitions in the 1st paragraph, a sustainable Supply Chain is a management of all flows (from suppliers to customers) that meets the 3 dimensions: Economic, Ecological and Social.

The level of interest in this approach and the environmental, economic and social concerns have become so widespread among individuals and companies (or among individuals WITHIN companies?) that it has become a crucial subject.

These concerns are motivated by the following main factors:

- Rising logistics costs (TCO – Total Cost of Ownership)

- Compliance with increasingly stringent government regulations

- More restricted market access if the company does not take the responsible turn

- The improvement of the company’s image and the benefit of competitive advantage

How to set up a sustainable Supply Chain?

Companies have not waited for a revolution in thinking to start working on the “economic” pillar.

The steps taken to optimize Supply Chain costs and performance have mechanically led to positive effects on ecology.

For example, the primary goal of Lean Management methods is to eliminate unnecessary tasks and waste, but also to reduce the consumption of energy, consumables, materials, etc. while improving productivity. Although the initiative is primarily economic, the impact is threefold because it is also environmental but also social by sustaining jobs.

The same applies to the optimization of transport plans, where more goods are transported with fewer transport units.

The initial goal is to reduce costs, but this will also improve the “environmental” pillar by reducing the carbon impact.

Less is more ?

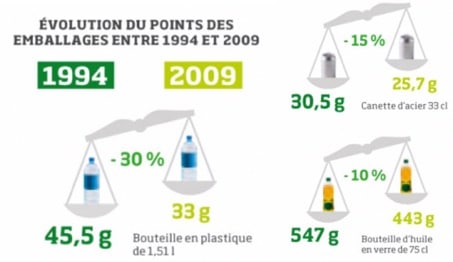

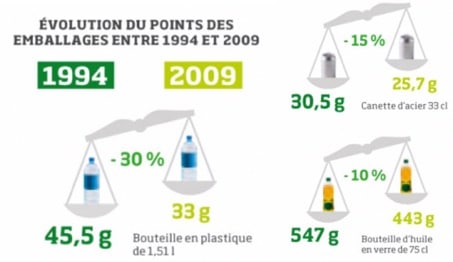

In the same vein, the optimization of packaging and containers is an approach that has been developed since the early 2000s. The primary objective remains to increase the filling rate by eliminating unnecessary volumes (always a very Lean approach, you might say…).

But at the same time, work on packaging is pushing companies to design solutions that are more environmentally friendly, i.e. lighter packaging, easily recyclable, made from recycled materials and/or green energy, locally sourced, etc.

Several sectors have already made great strides, such as fresh produce, bottled water and steel cans.

Taking the example of Activia and Taillefine yoghurts, which have eliminated their cardboard packaging in packs of four. In one year, this has saved 1,600 tons of cardboard!

Danone even estimated that beyond the ecological impact, the impact on sales was very positive (between +5% and +8%).

You therefore realize that Supply Chain management that is aware of its ecological and economic responsibility can bring significant improvements!

However, it must be acknowledged that the ecological dimension within Supply Chain departments still takes second or even third place. Profitability remains a priority, and knowing that the ecological impact is not directly reflected in logistics costs, decisions are not always favorable to our planet.

If ecological impact could be passed on to costs, this would considerably change strategies in terms of choice of transport and production sites with a considerable impact on the organization of our companies.

So, how bad is it, doctor?

To conclude, we can reassure ourselves that, even if Supply Chain optimizations are carried out primarily for economic reasons, they have a positive impact on the environment.

Moreover, recent and exponential technological developments also allow an acceleration of optimizations with ever sharper results (drones, artificial intelligence, 3D printing, etc.).

Finally, government regulations will force companies to pay greater attention to sustainability, and consumers are becoming more and more demanding with regard to the products they buy…

In this sense, we believe that a sustainable Supply Chain is the Future and that the sooner companies become aware of the stakes, the sooner the impact on our planet will be visible.

It is even an unprecedented opportunity to rethink our modes of production and innovate… to imagine that we can effectively combat climate change, initiate the ecological transition in the best conditions, preserve biodiversity, foster social cohesion and implement a new development dynamic on a global scale based on more economically, socially and environmentally responsible models.

However, we may not yet be ready to achieve this vision.

We continue to measure a company’s sustainability in terms of its profitability, and its social and environmental impact is still too often overlooked.

While everyone agrees that the Supply Chain is there to create Value for the company, does everyone share the idea that it must also create Value for society as a whole?

I’m not so sure about that.

We’re on the right track… but there’s still a long way to go.

Sustainable Supply Chains will become more widespread, of course, because it is indispensable. But what’s the timeframe? That is another question.

No doubt consumers will be at the origin of this new consumption revolution. Some have already taken the plunge, but on the other hand, we are increasingly favoring e-commerce purchases in convenience stores, and are looking for ever faster delivery. Product accessibility has become a priority.

Perhaps a human antagonism.

Will we have enough time to react … knowing the urgency of the situation as described by scientists?

Do not hesitate to share your views on the subject “Supply Chain + Sustainable Development = Happy Wedding?” with us!

What is sustainable development?

The first definition of sustainable development appeared in 1987 in the Brundtland Report published by the UN World Commission on Environment and Development:

“Sustainable development is development that meets the needs of the present without compromising the ability of future generations to meet their own needs.”

Concretely, sustainable development is a way of organizing society to enable it to exist in the long term. This implies taking into account both present and future imperatives such as the preservation of the environment and natural resources, or social and economic equity.

The objective of sustainable development is to define viable schemes that reconcile the ecological, social and economic aspects of human activities: “3 pillars” to be taken into account by communities as well as by companies and individuals.

The aim of sustainable development is to find a coherent and viable long-term balance between these 3 issues.

In other words, to ensure the sustainability of the model, development must be liveable, viable and equitable.

What is a Sustainable Supply Chain and Why?

By making the link with the definitions in the 1st paragraph, a sustainable Supply Chain is a management of all flows (from suppliers to customers) that meets the 3 dimensions: Economic, Ecological and Social.

The level of interest in this approach and the environmental, economic and social concerns have become so widespread among individuals and companies (or among individuals WITHIN companies?) that it has become a crucial subject.

These concerns are motivated by the following main factors:

- Rising logistics costs (TCO – Total Cost of Ownership)

- Compliance with increasingly stringent government regulations

- More restricted market access if the company does not take the responsible turn

- The improvement of the company’s image and the benefit of competitive advantage

How to set up a sustainable Supply Chain?

Companies have not waited for a revolution in thinking to start working on the “economic” pillar.

The steps taken to optimize Supply Chain costs and performance have mechanically led to positive effects on ecology.

For example, the primary goal of Lean Management methods is to eliminate unnecessary tasks and waste, but also to reduce the consumption of energy, consumables, materials, etc. while improving productivity. Although the initiative is primarily economic, the impact is threefold because it is also environmental but also social by sustaining jobs.

The same applies to the optimization of transport plans, where more goods are transported with fewer transport units.

The initial goal is to reduce costs, but this will also improve the “environmental” pillar by reducing the carbon impact.

Less is more ?

In the same vein, the optimization of packaging and containers is an approach that has been developed since the early 2000s. The primary objective remains to increase the filling rate by eliminating unnecessary volumes (always a very Lean approach, you might say…).

But at the same time, work on packaging is pushing companies to design solutions that are more environmentally friendly, i.e. lighter packaging, easily recyclable, made from recycled materials and/or green energy, locally sourced, etc.

Several sectors have already made great strides, such as fresh produce, bottled water and steel cans.

Taking the example of Activia and Taillefine yoghurts, which have eliminated their cardboard packaging in packs of four. In one year, this has saved 1,600 tons of cardboard!

Danone even estimated that beyond the ecological impact, the impact on sales was very positive (between +5% and +8%).

You therefore realize that Supply Chain management that is aware of its ecological and economic responsibility can bring significant improvements!

However, it must be acknowledged that the ecological dimension within Supply Chain departments still takes second or even third place. Profitability remains a priority, and knowing that the ecological impact is not directly reflected in logistics costs, decisions are not always favorable to our planet.

If ecological impact could be passed on to costs, this would considerably change strategies in terms of choice of transport and production sites with a considerable impact on the organization of our companies.

So, how bad is it, doctor?

To conclude, we can reassure ourselves that, even if Supply Chain optimizations are carried out primarily for economic reasons, they have a positive impact on the environment.

Moreover, recent and exponential technological developments also allow an acceleration of optimizations with ever sharper results (drones, artificial intelligence, 3D printing, etc.).

Finally, government regulations will force companies to pay greater attention to sustainability, and consumers are becoming more and more demanding with regard to the products they buy…

In this sense, we believe that a sustainable Supply Chain is the Future and that the sooner companies become aware of the stakes, the sooner the impact on our planet will be visible.

It is even an unprecedented opportunity to rethink our modes of production and innovate… to imagine that we can effectively combat climate change, initiate the ecological transition in the best conditions, preserve biodiversity, foster social cohesion and implement a new development dynamic on a global scale based on more economically, socially and environmentally responsible models.

However, we may not yet be ready to achieve this vision.

We continue to measure a company’s sustainability in terms of its profitability, and its social and environmental impact is still too often overlooked.

While everyone agrees that the Supply Chain is there to create Value for the company, does everyone share the idea that it must also create Value for society as a whole?

I’m not so sure about that.

We’re on the right track… but there’s still a long way to go.

Sustainable Supply Chains will become more widespread, of course, because it is indispensable. But what’s the timeframe? That is another question.

No doubt consumers will be at the origin of this new consumption revolution. Some have already taken the plunge, but on the other hand, we are increasingly favoring e-commerce purchases in convenience stores, and are looking for ever faster delivery. Product accessibility has become a priority.

Perhaps a human antagonism.

Will we have enough time to react … knowing the urgency of the situation as described by scientists?

Do not hesitate to share your views on the subject with us!

Need more information ?