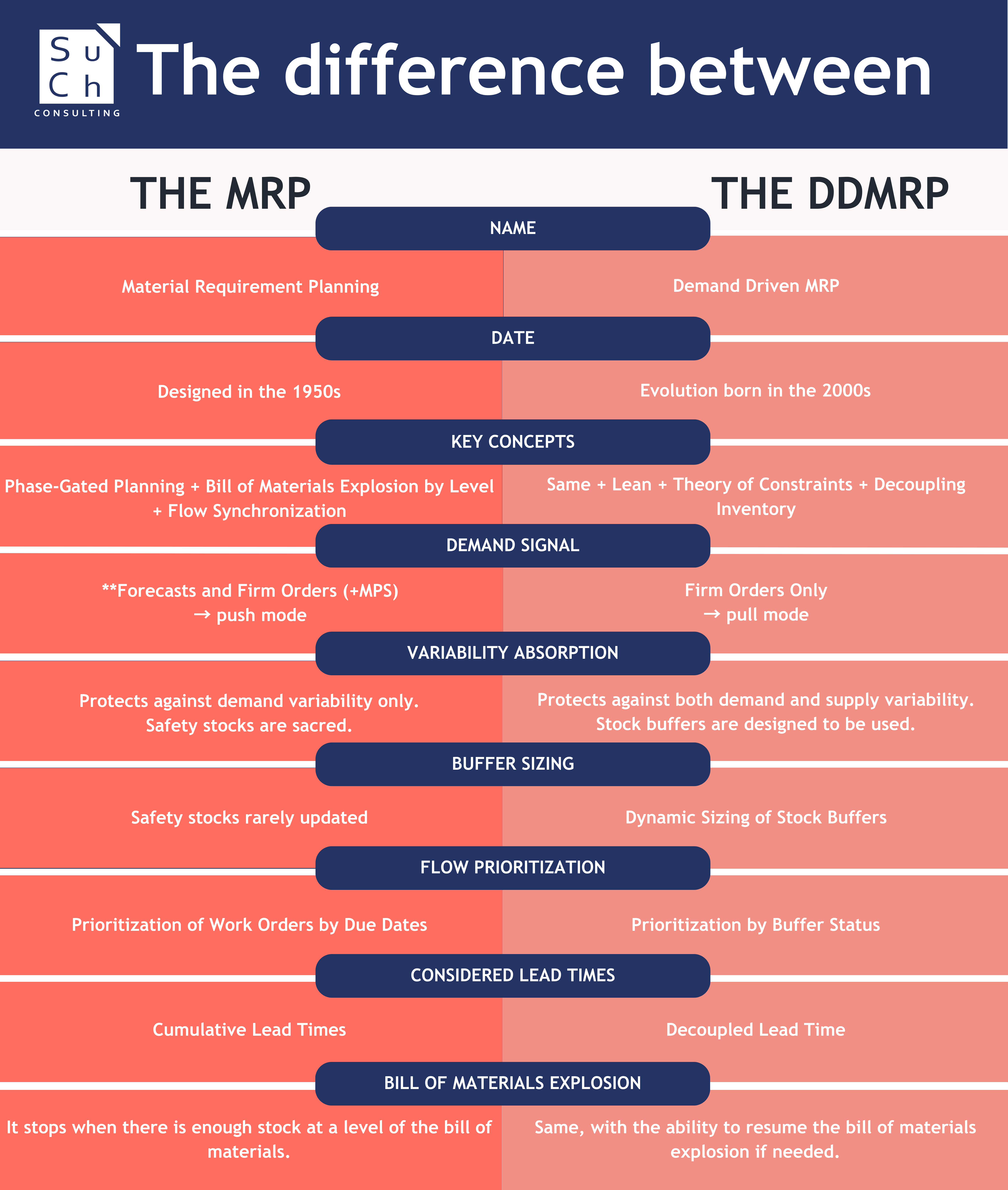

Demand Driven Material Requirements Planning (DDMRP) is a modern and innovative approach to supply chain management that combines elements of traditional material requirements planning (MRP) and lean manufacturing principles. It aims to enhance the responsiveness of supply chains to real-time demand changes, thereby reducing variability and improving overall performance.

How does DDMRP work?

- Strategic Inventory Positioning: By focusing on actual demand and real-time adjustments, DDMRP enables companies to respond more quickly to changes in customer requirements.

- Buffer Profiles and Levels: Defining buffer zones (green, yellow, red) for each inventory location to determine the appropriate stock levels. These zones are dynamically adjusted based on actual demand and supply conditions.

- Green Zone: Represents safety stock to absorb fluctuations

- Yellow Zone: The operational zone indicating that replenishment is needed.

- Red Zone: Represents critical safety stock, where immediate action is required to avoid stockouts.

- Demand-Driven Planning: Focusing on actual customer demand rather than forecasts to drive replenishment and production decisions.

- Visible and Collaborative Execution: Providing clear and actionable information to all stakeholders in the supply chain to ensure timely and effective execution.

-

Dynamic Adjustments: Continuously adjusting buffer levels using real-time data to respond to changes in demand, lead times, and supply variability.

DDMRP offers several significant advantages

Enhanced Responsiveness

By focusing on actual demand and real-time adjustments, DDMRP enables companies to respond more quickly to changes in customer requirements.

Reduced Inventory Levels

Strategic positioning of inventory buffers and dynamic adjustments help reduce excess inventory while maintaining service levels.

Improved Service Levels

Better alignment between supply and demand leads to higher service levels and customer satisfaction.

Increased Flexibility

The methodology allows companies to adapt to changes in the market and supply chain disruptions more effectively.

Simplified Planning Processes

DDMRP reduces the complexity of traditional MRP by focusing on critical inventory points and real-time data.

Implementing Demand-Driven Material Requirements Planning (DDMRP) within an organization is a strategic process that requires careful planning and execution. By following a structured approach, companies can successfully transition to this innovative inventory management methodology. The implementation involves several key steps, each crucial for ensuring that all stakeholders are aligned and that the system is tailored to the specific needs of the organization:

1. Education and Training: Ensuring that all relevant stakeholders understand the principles and benefits of DDMRP.

2. Assessment and Analysis: Conducting a thorough analysis of the current supply chain to identify critical points for buffer placement and areas of improvement.

3. Design and Planning: Developing a detailed plan for buffer placement, defining buffer profiles, and establishing metrics for performance measurement.

4. Pilot Implementation: Running a pilot program to test the DDMRP methodology in a controlled environment and gather initial data.

5. Full-Scale Implementation: Rolling out DDMRP across the entire supply chain, making necessary adjustments based on pilot results.

6. Continuous Improvement: Continuously monitoring performance and making dynamic adjustments to buffers and processes.

Several software solutions and tools are available to assist companies in implementing DDMRP:

- Demand Driven Technologies: Offers Replenishment+ and other solutions designed specifically for DDMRP.

- Orchestr8: Provides DDMRP software solutions and consulting services.

- Kinaxis: Their RapidResponse platform supports DDMRP alongside other supply chain planning functionalities.

- SAP Integrated Business Planning (IBP): Includes capabilities for implementing DDMRP within its suite of tools.

- DD Tech: A cloud-based solution tailored for DDMRP implementation.

DDMRP is applicable across various industries, each benefiting uniquely:

DDMRP significantly improves production planning and inventory management in the manufacturing industry, particularly in sectors characterized by complex and variable demand patterns. By offering a more reactive approach to inventory control, it enables manufacturers to optimize their resources and reduce lead times. In the retail sector, DDMRP improves stock positioning and effectively reduces out-of-stocks, which not only enhances customer satisfaction, but also boosts sales by ensuring constant availability of the most sought-after items.

In the pharmaceutical sector, DDMRP plays a crucial role in ensuring the availability of critical products while minimizing excess inventory and waste, thus improving overall supply chain efficiency and compliance with regulatory requirements. The automotive industry benefits from DDMRP by supporting just-in-time production, enabling manufacturers to precisely align their inventory levels with actual fluctuations in demand, thus reducing holding costs and increasing operational efficiency.

The manufacturing industry, especially sectors with high demand variability, such as aerospace, electronics or industrial equipment, particularly benefits from DDMRP. In these industries, production planning and inventory management are often complex, due to product diversity and order uncertainty. DDMRP enables more agile inventory management by strategically positioning buffers at different levels of the chain. This reduces the risk of stock-outs while maintaining a continuous production flow, even in the event of sudden fluctuations in demand.

For consumer goods, DDMRP is particularly effective in managing seasonal demand and promotional peaks, enabling companies to plan ahead and respond rapidly to changing market conditions. This adaptability helps improve stock rotation and reduce markdowns, which in turn improves profitability. Overall, DDMRP provides companies in a variety of sectors with a solid framework for managing their supply chains more effectively in an increasingly dynamic market environment.

Implementing DDMRP can present several challenges:

- Cultural Resistance: As with any transformation in business processes, change is often viewed with skepticism. Employees, especially those accustomed to traditional methods such as conventional MRP or just-in-time (JIT), may be reluctant to adopt this new approach. It is essential to overcome this resistance by highlighting the benefits of DDMRP and engaging stakeholders in in-depth training programs.

- Initial Investment: Implementing DDMRP requires significant investment, not only in terms of technology and software, but also in training staff and adjusting existing processes. Companies must be prepared to revise their IT infrastructure to integrate DDMRP-based solutions, such as ERP modules or real-time supply chain planning systems.

- Data Accuracy: DDMRP relies on accurate, real-time data. If existing systems are fragmented or obsolete, or if data flows are unreliable, this can lead to errors in buffer positioning or inappropriate replenishment decisions. Ensuring data quality is therefore a prerequisite for DDMRP success.

- Change Management: Transformation to DDMRP requires good change management. Companies need to prepare a solid communication plan to align teams, monitor progress and adjust the methodology according to feedback. Effective strategies must be deployed to ensure that staff fully understand how DDMRP works and adhere to the new practices.

- Integration with Existing Systems: Companies already using ERP or supply chain management systems may find it difficult to integrate DDMRP solutions. It’s essential to ensure that the new tools fit well into the existing digital ecosystem, without creating silos or data redundancies.

Companies that have adopted DDMRP report several positive outcomes:

Businesses achieve significant reductions in inventory levels without compromising service levels, enabling improved inventory management. They also benefit from an increased ability to respond rapidly to customer demand, resulting in higher service levels. Savings are achieved through lower storage costs and fewer expedited shipments, while improved visibility of supply chain performance enables better management of potential disruptions. In addition, companies benefit from greater flexibility to adapt to market changes and supply chain variability.

How does DDMRP integrate with other supply chain management concepts, such as inventory management, sales and operations planning (S&OP), and demand management?

DDMRP integrates seamlessly with various supply chain management concepts:

- Inventory Management: DDMRP enhances traditional inventory management by adding a dynamic dimension to inventory level adjustments. It adds strategically positioned buffers, based on actual demand flows rather than forecasts. This helps maintain inventory at optimal levels without creating surpluses, while improving responsiveness to variations.

- Sales and Operations Planning (S&OP): DDMRP integrates seamlessly with sales and operations planning, providing accurate, real-time information on stock levels and replenishment requirements. This data helps to better align supply and demand in the short and medium term, improving forecasting and reducing imbalances between production and actual requirements.

- Demand Management: DDMRP improves demand management by relying on real demand signals, rather than uncertain forecasts. This enables companies to anticipate customer needs more accurately and better adapt production and replenishment processes, thus reducing planning errors and inefficiencies.

Courses and certifications available for professionals:

- Demand Driven Institute (DDI): Offers a range of training programs and certifications, including Demand Driven Planner (DDP) and Demand Driven Leader (DDL).

- APICS/ASCM: Provides DDMRP training as part of their Certified Supply Chain Professional (CSCP) and other certification programs.

- Local Universities and Training Providers: Many universities and professional training organizations offer courses on DDMRP and related topics.

Our consultants, Marc Such and Caroline Pagnier, are certified DDP (Demand Driven Planner) experts, ensuring professional, expert support in implementing DDMRP for your company.

Conclusion

In summary, DDMRP is a powerful methodology that addresses many of the challenges associated with traditional supply chain planning. By focusing on actual demand and using real-time data, it enhances responsiveness, reduces inventory, and improves overall supply chain performance. Implementing DDMRP requires careful planning, investment in training and tools, and effective change management, but the benefits make it a compelling choice for companies looking to modernize their supply chain operations.